Tactile design can use a lot of different production processes. This card is both blind embossed and letterpress printed. Many people incorrectly use the term “emboss” when speaking about letterpress printing. “Emboss” actually refers to a raised area accomplished by use of a two part die with a form and a counter form. Letterpress printing with heavy impression is closer to a “deboss.” A deboss is pushing down into the paper. (remember “d” for down = deboss) Letterpress plates can use ink but embossing and debossing dies do not use ink. They must be used blind, registered to preprinted artwork or used with foil stamping / blocking.

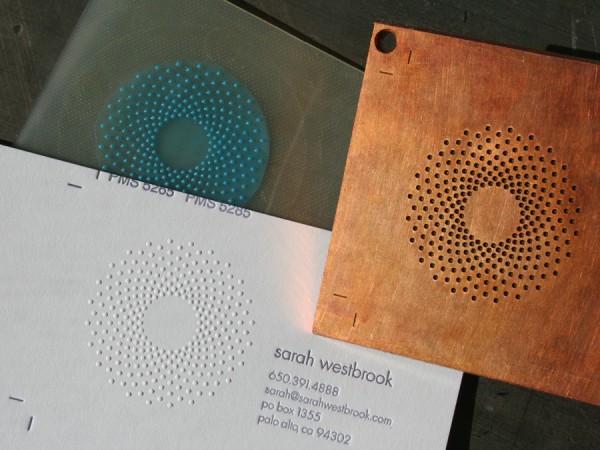

Letterpress equipment can be used for embossing, debossing and letterpress printing, with the correct dies. Unlike embossing and debossing, letterpress plates do not use a form and counter form. A letterpress plate is inked and pressed down into the sheet. See an image below with the polymer plate and its corresponding print and note the difference from the copper embossing die with a white and blue fiberglass counter form that made the circular design embossed on this card. These are two very different types of plates and printing effects, but run on the same Heidelberg windmill press.

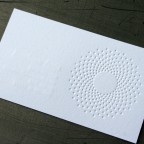

Considering each side of the page is an important design consideration with tactile production processes. With letterpress plates, the amount of bruising or “show through” on the back of the print depends on the amount of pressure applied during printing. However, this definition on the reverse side of the sheet is different on embossing dies because there is a counter form that pushes into the sheet.

When an emboss is specified there are a few other considerations we would mention. Smaller sized artwork, say 12 point type and smaller offers very little raised definition. Paper thickness is also a concern. We like really thick stocks for letterpress printing, but when embossing that thickness makes it even more difficult to get good definition in smaller details. This paper was 134lb Crane Cover Flo. White, it is 100% cotton and offers a soft and sculptured impression.